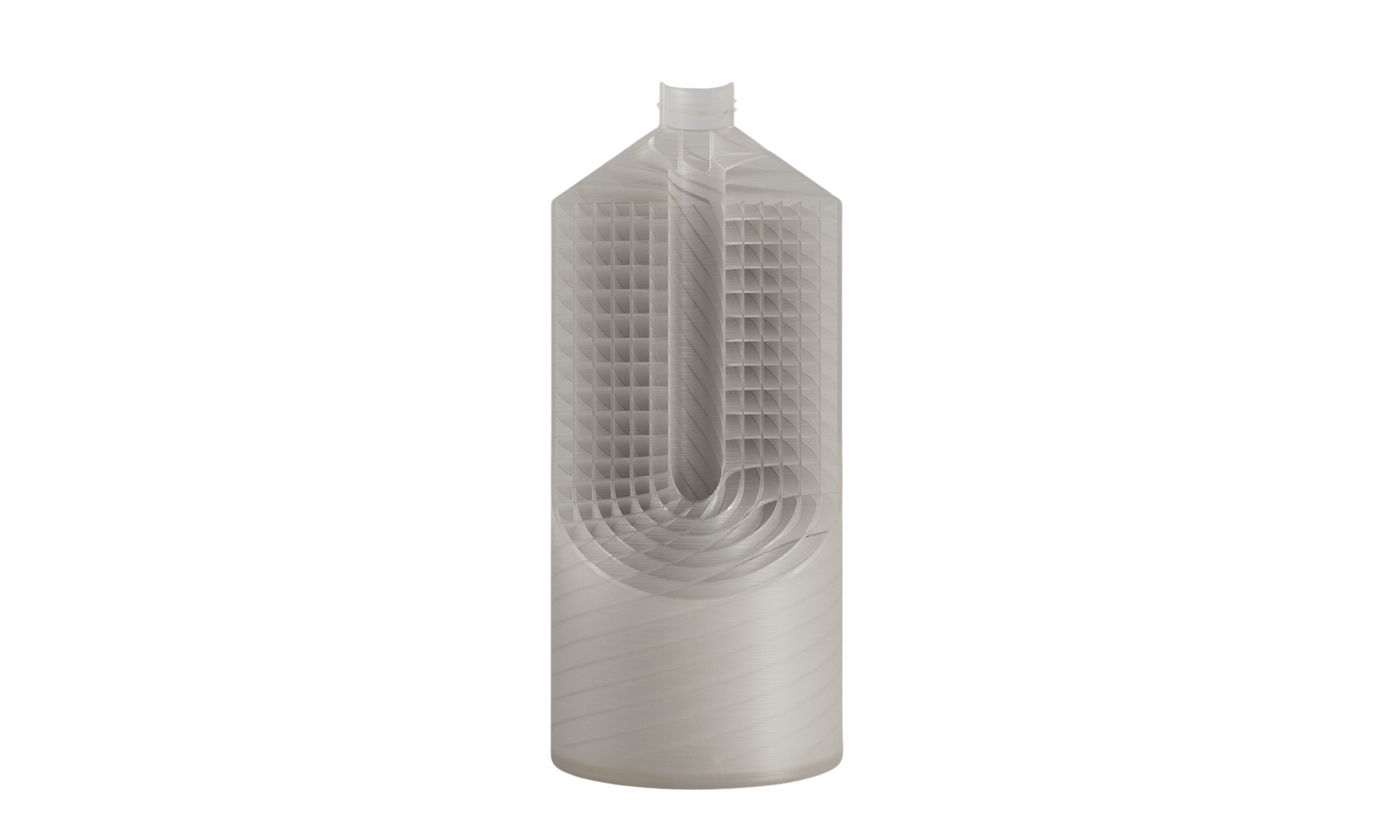

CellScrew®

Optimize your adherent cell expansion system with the sustainable and scalable CellScrew®, made from plant-based plastic. It is the ideal solution to reduce manufacturing costs, time to market, and environmental impacts.

- Compact design for easy handling

- Archimedean screw for gas exchange and mixing

- Concentric cylinders forming a large cell culture area

Watch the Video

Learn how the CellScrew® creates easy-to-automate low shear mixing using plant-based plastic in the video above.

Optimal Adherent Cell Attachment Conditions

With a combination of a central tube, an Archimedean Screw, and Concentric Cylinders, the innovative structure creates a continuously mixed, highly oxygenated environment.

Overview

With reduced manufacturing costs, reduced time to market, and reduced environmental impact, our CellScrew® from Green Elephant is the ideal solution for your adherent cell expansion system needs. The CellScrew® features a large growth surface, which allows for optimal cultivation conditions, and allows for scale-up. The system is made from plant-based PLA and is composed of a central tube, concentric cylinders, and an Archimedean screw.

Our CellScrew® follows an easy three-step process of inoculation, incubation, and the resulting harvest. The system requires little additional equipment to be automated, reducing the use of manufacturing space and labor costs. It can be scaled from 6,000-10,000cm2 of cell culture area, maintaining a high surface area to volume ratio.

Features & Benefits

- Low shear

- Extensively scalable

- 3D printed construction

- Plant-based PLA bioplastic

- Large growth surface area made of concentric cylinders

- Reduced manufacturing costs and time to market

- 90% less plastic waste

- 90% reduction in CO2 emissions compared to conventional multilayer flasks

- Can be automated with little outside equipment

- Archimedean screw for excellent mixing and gas exchange

- Cell culture area from 6,000-10,000cm2

- High surface area to volume ratio

- Easy handling with compact design

Documents

Applications

- Vaccine manufacturing

- Drug screening and development

- Adherent cell expansion

Technical Specs

| Height | 191.1 mm |

| Diameter | 121 mm |

| Cylinder Height | 138.1 mm |

| Konus Height | 31.8 mm |

| Konus Angle | 35° |

| Cap Diameter | 39 mm |

| Cap Height | 24 mm |